Home > Solegewinnung > KALISOLUNG UND SONDERSALZE

Mehr als nur Salz

Die Gewinnung von Steinsalz, Kalisalz, Trona und anderen mineralischen Rohstoffen im Lösungsbergbau weist im Vergleich zum konventionellen Bergbau entscheidende Vorteile auf: Die soltechnische Gewinnung ist kostengünstiger und wesentlich sicherer. Aufwendige Grubenbaue sind nicht erforderlich, der Personaleinsatz ist erheblich geringer. Die gewonnenen Rohstoffe werden vielfältig eingesetzt: Sole wird zu Speise- oder Auftausalz verarbeitet, in der chemischen und pharmazeutischen Industrie eingesetzt oder zur Düngemittel-Herstellung verwendet.

Planungssicherheit schaffen

Erkundungsbohrungen, Ressourcenberechnungen und Wirtschaftlichkeitsbetrachtungen liefern die Entscheidungsgrundlagen, ob ein Solegewinnungs-Projekt zu realisieren ist. Technische Planungen verfeinern das Bild. Damit ist der Betreiber in der Lage, langfristig zu planen.

Die Lösung ist nicht immer einfach

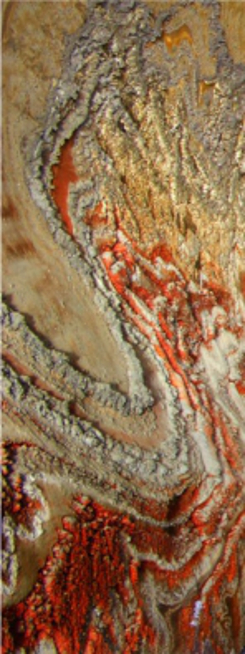

Salzkavernen im Lösungsbergbau erfordern ein sehr differenziertes Wissen. Auch wenn sich im Labor Salz optimal auflösen lässt, ist in der Natur nicht mit einer optimalen Gesteinszusammensetzung und Mineralkonzentration zu rechnen. Die geologischen Bedingungen geben uns den Rahmen vor; chemische, physikalische und thermodynamische Faktoren beeinflussen, wie intensiv die Lagerstätte genutzt werden kann und welche Reststoffe in welchen Mengen anfallen. Entscheidend für die Wirtschaftlichkeit eines Betriebes und die Produktgüte sind sowohl das passende Solverfahren als auch die sorgfältige Planung des Lösungsprozesses.

Daher setzt die DEEP.KBB auch im Lösungsbergbau auf ein umfassendes, interdisziplinäres Vorgehen: Geowissenschaftler und Ingenieure erarbeiten gemeinsam im Labor und mit Hilfe von 3D-Computersimulationen das auf die jeweilige Lagerstätte optimal abgestimmte Gewinnungsverfahren.